pdf 7.3 powerstroke wiring diagram

The 7.3 Powerstroke wiring diagram is a detailed guide for understanding the electrical system of Ford trucks equipped with the 7.3L diesel engine. It provides a visual representation of wire connections, circuits, and components, aiding in diagnostics, repairs, and custom modifications. This essential resource is invaluable for mechanics and DIY enthusiasts, ensuring accurate troubleshooting and maintaining optimal engine performance.

Overview of the 7.3 Powerstroke Engine and Its Electrical System

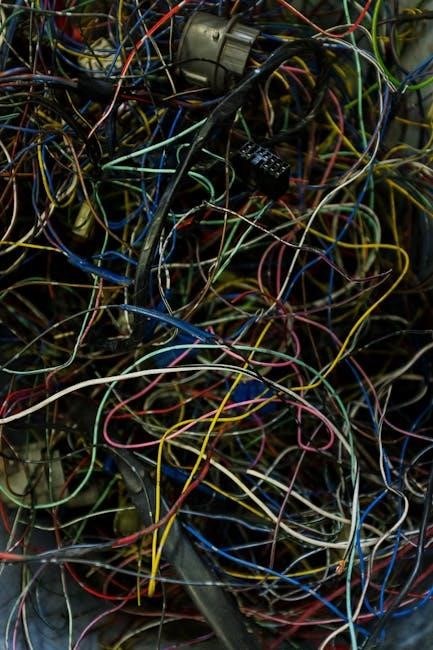

The 7.3 Powerstroke engine, renowned for its reliability and durability, powers Ford trucks like the F-250 and F-350. Its electrical system is complex, managing fuel injection, emissions, and diagnostics. The Engine Control Module (EEC-V) oversees operations, ensuring optimal performance. Wiring diagrams are crucial for understanding connections between sensors, actuators, and components. The system includes high-tech features like glow plug controllers and fuel injectors, requiring precise electrical signaling. With its robust design, the 7.3 Powerstroke’s electrical system supports heavy-duty applications, making it a favorite among truck enthusiasts. Proper maintenance relies on accurate wiring schematics, ensuring longevity and peak functionality.

Importance of Wiring Diagrams for Maintenance and Repairs

Wiring diagrams are indispensable for maintaining and repairing the 7.3 Powerstroke engine. They provide a clear, visual representation of the electrical system, helping technicians identify circuits, connectors, and components. With a wiring diagram, diagnosing issues like faulty sensors or short circuits becomes efficient. It guides mechanics through complex repairs, ensuring accuracy and reducing downtime. For DIY enthusiasts, these diagrams are a lifeline, offering step-by-step solutions for troubleshooting. Regular maintenance also benefits from these schematics, as they highlight critical connections that need inspection. Overall, wiring diagrams are essential tools for preserving the engine’s performance and extending its lifespan.

Understanding the Wiring Diagram Layout

The 7.3 Powerstroke wiring diagram layout organizes electrical circuits, connectors, and components visually. Symbols and color coding simplify navigation, aiding professionals and DIYers in understanding the engine’s electrical system.

Key Components and Symbols Used in the Diagram

The 7.3 Powerstroke wiring diagram features essential components like connectors, wiring harnesses, and electronic control modules. Symbols such as circles for connectors, lines for wires, and boxes for components simplify interpretation. Color-coded wires indicate specific functions, while labels provide clarity. The diagram includes detailed connector views, such as those for the 1997 F350 (P11 and P21) and 2001 F250, ensuring accurate identification. These symbols and labels help users trace circuits, diagnose faults, and perform repairs efficiently. The clear layout and standardized symbols make the diagram accessible to both professionals and DIY enthusiasts, ensuring precise electrical system understanding and maintenance for the 7.3L Powerstroke engine.

How to Read and Interpret the Wiring Schematic

Reading the 7.3 Powerstroke wiring diagram requires identifying key components and understanding their connections. Start by locating the power source and tracing circuits through connectors and components. Color-coded wires indicate specific functions, such as power, ground, or signal lines. Use the legend to interpret symbols, like circles for connectors or rectangles for modules. Cross-reference the diagram with the vehicle’s electrical system to pinpoint faults or plan modifications. For example, the 1997 F350 P11 and P21 diagrams detail specific connector views, while the 2001 F250 schematic focuses on system integration. This systematic approach ensures accurate diagnostics and efficient repairs, making the diagram indispensable for professionals and DIY enthusiasts alike.

Model-Specific Wiring Diagrams

The 7.3 Powerstroke wiring diagrams vary by Ford model and year, such as the 1997 F350, 2001 F250, and 2004 F250, ensuring accurate repairs and modifications.

1997 Ford F350 7.3L Wiring Diagram (p11 and p21)

The 1997 Ford F350 7.3L wiring diagrams, labeled as p11 and p21, provide detailed electrical schematics for the vehicle’s systems. These diagrams are essential for troubleshooting and repairs, offering a clear layout of circuits, connectors, and components. The p11 diagram focuses on the basic electrical systems, while the p21 delves into more complex systems like the Powerstroke engine’s electronic controls. Both diagrams are available as downloadable PDFs, making them easily accessible for mechanics and DIY enthusiasts. They cover everything from battery connections to engine management systems, ensuring accurate diagnostics and efficient fixes. These resources are indispensable for maintaining and upgrading the 1997 F350’s performance and reliability.

2001 Ford F250 Super Duty Wiring Diagram

The 2001 Ford F250 Super Duty wiring diagram is a comprehensive guide for the electrical systems of this model. It includes detailed schematics for the 7.3L Powerstroke engine, covering circuits for fuel injection, emissions, and electronic controls. The diagram is organized into sections, making it easier to locate specific components like sensors, relays, and connectors. Available as a downloadable PDF, this resource is crucial for diagnosing issues such as faulty sensors or wiring malfunctions; Mechanics and enthusiasts can use it to trace circuits, identify connectors, and perform repairs efficiently. This wiring diagram ensures accurate troubleshooting and maintenance, keeping the Super Duty running at peak performance.

2004 Ford F250 Super Duty Wiring Diagram

The 2004 Ford F250 Super Duty wiring diagram provides a detailed guide for the 7.3L Powerstroke engine’s electrical system. It includes connector views and labeled figures, ensuring clarity for diagnostics and repairs. Available as a downloadable PDF, this resource is essential for understanding the complex wiring layout of the vehicle.

Connector Views and Identification Figures

Connector views and identification figures are crucial for understanding the wiring layout of the 7.3 Powerstroke engine. These detailed diagrams provide visual representations of various connectors, showcasing their pin layouts and wire colors. They help technicians and DIY enthusiasts identify electrical connections quickly, ensuring accurate diagnostics and repairs; The figures are often labeled with specific codes and descriptions, making it easier to trace circuits and resolve issues. Available in PDF formats, these resources are widely accessible and provide a clear reference for troubleshooting common electrical problems. They are indispensable for anyone working on the 7.3L Powerstroke engine, ensuring precise and efficient electrical system maintenance.

Labeled Figures for Connectors and Electrical Connections

Labeled figures for connectors and electrical connections provide a clear and precise visual guide for the 7.3 Powerstroke wiring diagram. These detailed diagrams are essential for identifying each connector’s function, wire color codes, and pin configurations. They are often included in PDF resources, offering a comprehensive overview of the electrical system. By referencing these figures, technicians and enthusiasts can efficiently diagnose and repair issues, such as faulty connections or damaged wires. The labels ensure accuracy, reducing the risk of misidentification. These figures are particularly useful for complex systems like the 7.3L Powerstroke, where multiple connectors and circuits must be carefully managed to maintain optimal performance and reliability.

Heavy-Duty Connectors in the 7.3 Powerstroke

Heavy-duty connectors in the 7.3 Powerstroke are designed to handle high electrical loads and harsh environments. They ensure reliable connections between engine components and the vehicle’s electrical system, minimizing the risk of failure. These connectors are built with durable materials and are sealed to protect against dust, water, and temperature fluctuations. Proper maintenance and inspection of these connectors are crucial for maintaining optimal engine performance and preventing electrical issues. Regularly checking for signs of wear or corrosion can help prevent unexpected failures and ensure the longevity of the vehicle’s electrical system.

Role of Heavy-Duty Connectors in Electrical Systems

Heavy-duty connectors play a pivotal role in the electrical systems of the 7.3 Powerstroke engine, ensuring robust and reliable connections between various components. These connectors are designed to withstand the rigorous demands of high-current applications, providing a secure interface for power transmission. They effectively shield against environmental factors such as moisture, dust, and temperature variations, which could otherwise compromise electrical integrity. By maintaining consistent signal and power flow, heavy-duty connectors are essential for the proper functioning of critical systems like fuel injection, ignition, and emissions control. Their durability and reliability make them indispensable in maintaining the overall performance and efficiency of the engine.

Common Issues and Solutions for Connector Failures

Connector failures in the 7.3 Powerstroke engine often stem from corrosion, wear and tear, or overheating. Corrosion can disrupt electrical signals, while worn connectors may lose their grip, leading to intermittent connections. Overheating can damage the connector’s internal components, causing permanent failure. To address these issues, regular inspection and cleaning of connectors with a wire brush are recommended. Applying dielectric grease can prevent corrosion and ensure reliable connections. For worn or damaged connectors, replacement with high-quality, OEM-spec parts is essential. Proper torque specifications should be followed during installation to avoid overheating. Addressing these issues promptly helps maintain electrical system integrity and prevents further complications down the line.

Diagnostic Guide for Powertrain Control System

The guide provides detailed steps for diagnosing powertrain control system faults, using wiring diagrams to trace electrical issues in 7.3L engines, covering 1997-2004 models.

Electronics Faults and Troubleshooting Tips

Electronics faults in the 7.3 Powerstroke often stem from faulty sensors, poor connections, or malfunctioning control modules. Common issues include the Idle Air Control (IAC) sensor failure, causing rough idling, and Crankshaft Position Sensor (CKP) faults, which can prevent engine starting. Troubleshooting involves consulting the wiring diagram to trace circuits and verify sensor communication; Check for loose or corroded connectors, as these are frequent sources of electrical failures. Use an OBD-II scanner to retrieve fault codes for precise diagnostics. Visual inspections and voltage tests can identify wiring issues, such as shorts or open circuits. Always refer to the wiring diagram to ensure accurate repairs and maintain system functionality.

Using Wiring Diagrams for Diagnostic Procedures

Wiring diagrams are indispensable for diagnosing electrical issues in the 7.3 Powerstroke engine. They provide a clear visual map of the electrical system, allowing technicians to trace circuits and identify faulty components. By referencing the diagram, one can pinpoint where a short, open, or ground might occur; For example, if the engine fails to start, the diagram can guide checks of the starter motor circuit, including the ignition switch, relays, and battery connections. Using an OBD-II scanner alongside the wiring diagram helps isolate electronic control module faults. This systematic approach ensures accurate troubleshooting, saving time and reducing guesswork during repairs. It is a vital tool for both professionals and DIY enthusiasts.

Downloading and Accessing Wiring Diagrams

Wiring diagrams for the 7.3 Powerstroke are widely available online in PDF format. Reliable websites offer free downloads, including detailed schematics for specific Ford models like the 1997 F350 and 2001 F250.

Free Resources for PDF Wiring Diagrams

Several websites and forums offer free PDF wiring diagrams for the 7.3 Powerstroke engine, catering to various Ford models like the 1997 F350 and 2001 F250. These resources provide detailed schematics, including connector views and electrical connections, making DIY repairs and troubleshooting easier. Platforms like forums and specialized automotive websites host these documents, ensuring accessibility for enthusiasts and mechanics. For instance, the 1997 F350 wiring diagrams (p11 and p21) are widely available, along with labeled figures for connectors. These free resources are a valuable tool for maintaining and modifying the 7.3L engine, offering a comprehensive guide for electrical system diagnostics and repairs.

Reliable Websites for 7.3 Powerstroke Wiring Schematics

Reputable websites provide accurate and detailed wiring schematics for the 7.3 Powerstroke engine, serving as essential tools for mechanics and enthusiasts. Sites like Ford’s official service portal and specialized forums offer downloadable PDFs, including diagrams for specific models such as the 1997 F350 and 2001 F250. These resources often include connector views and labeled figures, ensuring clarity and ease of use. Additionally, platforms like Scribd and automotive repair forums host extensive libraries of wiring diagrams. Ensuring the use of trusted sources is crucial for accurate repairs and modifications, making these websites indispensable for maintaining the 7.3L engine’s electrical system effectively.

The 7.3 Powerstroke wiring diagram is an essential tool for DIY enthusiasts and professionals. It simplifies complex electrical systems, aiding efficient repairs and modifications. Use reliable sources for accurate schematics to maintain performance and avoid costly errors. Downloadable PDFs and detailed connector views provide a seamless troubleshooting experience.

Final Thoughts on the Importance of Wiring Diagrams

Wiring diagrams are indispensable for maintaining and repairing the 7.3 Powerstroke engine. They provide a clear, visual understanding of the electrical system, ensuring accurate diagnostics and efficient repairs. Whether you’re a professional mechanic or a DIY enthusiast, these diagrams are crucial for avoiding costly mistakes. By referencing reliable PDF resources and websites, you can access detailed schematics tailored to your specific vehicle. This not only saves time but also enhances safety by preventing electrical mishaps. Embrace the convenience of downloadable wiring diagrams to keep your 7.3 Powerstroke running smoothly and maintain its legendary performance for years to come.

Encouragement to Use Diagrams for DIY Repairs

Using wiring diagrams for DIY repairs empowers you to take control of maintaining your 7.3 Powerstroke engine. These visual guides simplify complex electrical systems, reducing guesswork and saving time. Whether you’re a seasoned mechanic or a novice, diagrams provide clarity, ensuring repairs are done safely and efficiently. They help identify connectors, trace circuits, and diagnose faults accurately. With free PDF resources and reliable websites offering detailed schematics, DIY enthusiasts can tackle projects with confidence. Fixing issues yourself not only saves money but also builds knowledge and satisfaction. Embrace the convenience of wiring diagrams to keep your truck running smoothly and extend its lifespan. DIY repairs have never been more accessible!